Measurement technology on flying platforms: Laser Doppler vibrometer with external laser and radio transmission

DFG

State of the art

Laser Doppler vibrometry (LDV) is the most precise method for non-contact vibration measurement. In current research projects - such as the DFG project "Flyable Mirror" [1] - the measurement technology is already being combined with drones to examine large structures or structures that are difficult to access. Typically, ground-based LDV systems are used, whose measuring beam is guided to the measuring point via a mirror attached to the drone. The raw optical data obtained (interference signals) are transmitted optically via the direct laser system to the ground station, where the actual signal processing and evaluation takes place.

However, these approaches have their limits: Measurement accuracy is limited by interference along the long optical paths between the ground and the drone, e.g. atmospheric turbulence, temperature fluctuations and vibrations of the platform itself. In addition, high-precision LDV systems require powerful lasers with a long coherence length, which are currently unsuitable for direct installation in a drone due to their size, weight and energy consumption.

Goal of our project

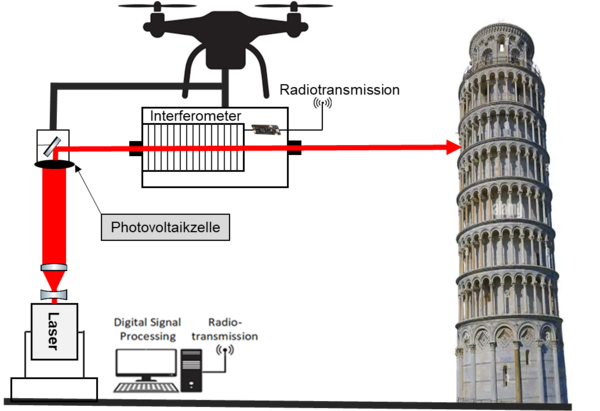

Our ambitious goal is to develop a novel, high-precision and fully airworthy laser Doppler vibrometer that combines two key innovations: the decoupling of power supply and sensor technology and robust wireless data transmission. The powerful laser remains on the ground, while only the compact, energy-efficient interferometer setup is placed on the drone. The laser beam is also used to transmit energy to the drone. For the first time, the high-resolution measurement data obtained on the drone is transmitted to the ground station in real time via a secure radio link.

This concept enables:

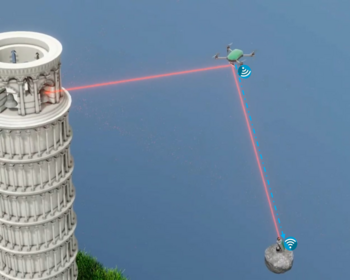

- Outstanding measurement accuracy: minimization of interference due to short optical paths between drone and measurement object.

- Maximum flexibility & freedom of movement: Use of any drone platform, regardless of its on-board power supply. Radio transmission frees the system from the need for a direct optical connection to the ground station during the flight.

- Robustness under real conditions: The system is insensitive to interruptions in the line of sight for data transmission and enables operations behind obstacles or in complex terrain.

- Future expandability: The concept creates the basis for the later integration of active vibration excitation via laser pulse to enable targeted and more sensitive fatigue detection in structures.

Methods & our approach

The project builds on the team's unique expertise and groundbreaking preliminary work:

- Core competence in laser Doppler vibrometry: under the leadership ofProf. Dr.-Ing. Christian Rembe, an internationally recognized expert with over 20 patents and 90 publications in this field, the "Applied Metrology" group at Clausthal University of Technology has been researching LDV for demanding environments for years. One focus is on the suppression of interference, e.g. through differential measurement methods (DLDV) and the compensation of the laser speckle effect.

- Proven drone expertise: In close cooperation with the German Aerospace Center (DLR), in particular with Prof. Dr. Umut Durak and Dr. Mohamed Ismail, initial measurements have already been successfully carried out with commercial LDV systems and flying mirrors. This work provides the fundamental basis for system integration on UAVs.

- Innovative transfer concept: In the new approach, the laser beam is precisely coupled from the ground to the optics on board the drone via a tracking system. A highly efficient photovoltaic cell arranged around the entry aperture converts part of the laser power into electrical energy for the sensor. This makes the system self-sufficient.

- The interferometer on the drone is compact, lightweight and low-consumption.

- The powerful laser on the ground ensures the necessary coherence and a low-noise measurement.

- High-performance radio data transmission: A central development focus is the implementation of a reliable, high-bit-rate and low-latency radio link for transmitting the processed vibration data to the ground station. This key component is made possible by close collaboration with Prof. Dr.-Ing. habil. Niels Neumann. With his professorship for communication technology for the Industrial Internet of Things (IIoT), more than 100 scientific publications and seven patent applications, he brings excellent expertise to the development of robust, industrial-grade data links. Together, modern transmission protocols and advanced error correction methods are used to ensure data integrity and real-time capability even under difficult radio conditions.

- Comprehensive analysis: The development is accompanied by a detailed analysis of the measurement uncertainty as well as experimental investigations into atmospheric interference and vibration excitation. This ensures the reliability and precision of the new technology under real-life conditions.

This project is being carried out in a protected research environment and the detailed technical specifications, design details and ongoing results are subject to confidential agreements between the project partners. Our goal is to set new standards in non-destructive testing and aerial structural monitoring with this groundbreaking technology that combines precision metrology, wireless data communication and UAV platforms.

If you are interested in a cooperation or further information, please contact us directly.

[1] Schewe, M., Ismail, M. A. A., Zimmermann, R., Durak, U, Rembe, C. (2023). Flyable Mirrors: towards the first airborne laser Doppler vibrometry for large engineering structures, Int. Conf. on Vibration Measurements by Laser and Noncontact Techniques, Ancona, Italy, 21-23 June 2023. Proc. to be published in the IOP Conference Series.

Rosver Daniel Sando Fogno, M.Sc.

Research Assistant

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/b/2/csm_KT_MPV_1a049c53c4.jpg)