Fabrication of Micro Optical Sensors from Polymers

Scope (excerpt)

- Selection and comparison of polymer materials

- Optimization of production techniques and processes

- coating

- exposure

- thermal treatment

- pre and post processing

- development and optimization of test procedures

- Production of polarization-maintaining polymer waveguides

- simulation

State of the Art/Motivation

- Modern polymers are highly versatile materials and metamaterials. They can be specifically tailored to meet different demands. Hence, they are very well suited for production of electronic, mechanical and optical micro components. Modification can be achieved, for example, by

- embedding nano particles

- structuring molecular chains

- combining different materials

- Polymeric MEMS (MicroElectroMechanical Systems) are already state of the art

- Integrated single-mode optical waveguides are currently mainly realized in semiconductor materials

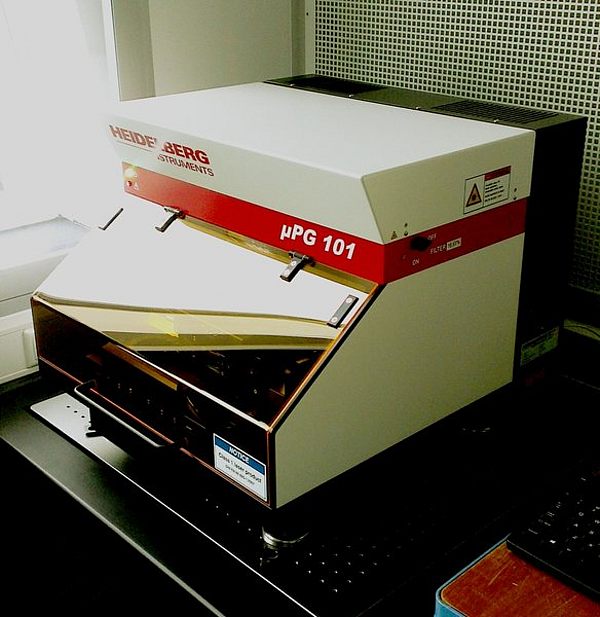

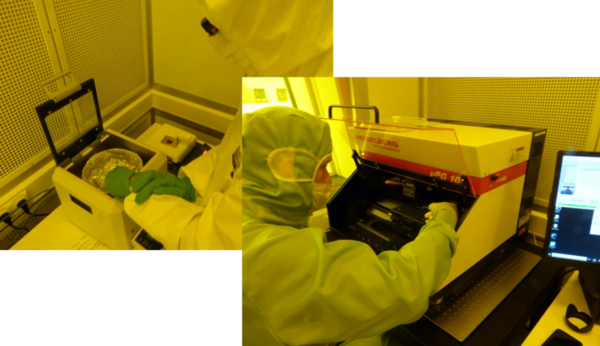

- Newest systems for laser lithography are capable of structuring polymeric films with sub-micron resolution even without the use of masks

Methods

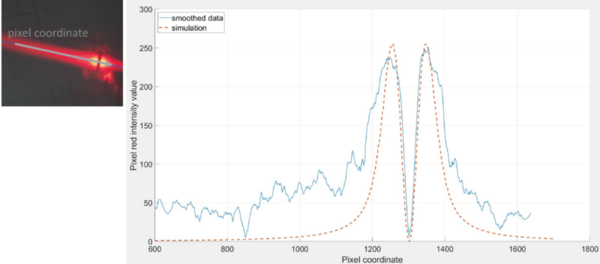

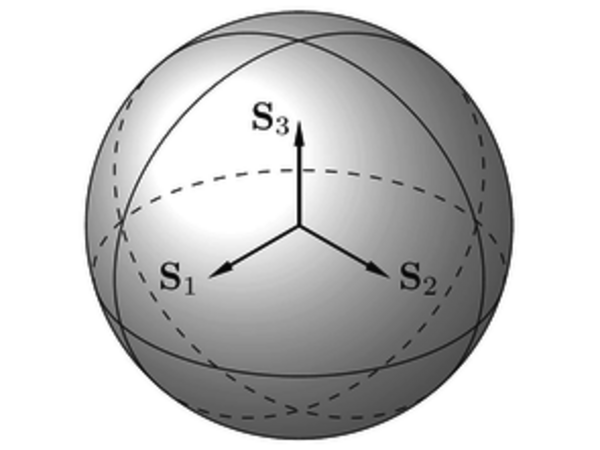

- Evaluation of methods for invoking birefringence in polymers to create polarization maintaining polymer waveguides

- Coupling of linearly polarized laser light into the produced waveguides and investigation of the polarization extinction ratio in respect to environmental influences

Background

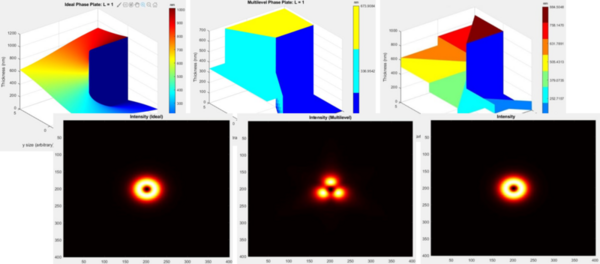

A so-called „Doughnut Mode“ is a laser beam with an area in its centre, where there is no light. This type of intensity distribution is used, for example, in modern microscopy, fabrication techniques and holography.

State of the art

Doughnut Modes can be created via different means. One method are so-called phase plates, where the plate’s thickness (and thereby, the thickness of material a laser beam passes through) changes over the tangential direction.

- Optical phase plates are passive elements, which shape a laser beam in a specific manner. They delay a laser beam in such a way that it interferes with itself, creating an area of (near) total extinction.

- Phase plates can be made from glass or polymers, for example.

- Due to high demands in precision, they are usually quite costly.

Excerpt from tasks, methods and results

- Simulation of an optical phase plate.

- Optimizing and design of a phase plate with the simulation.

Publications

- T. Ziemer, D. Leitz, J. Nijim und C. Rembe:

Fertigung polymerer optischer Phasenplatten zur Erzeugung von Ringmoden mittels direkter Laserlithografie

In: tm - Technisches Messen. Vol. 87, Issue s1, pp. 34-39, Aug. 2020. DOI: 10.1515/teme-2020-0014

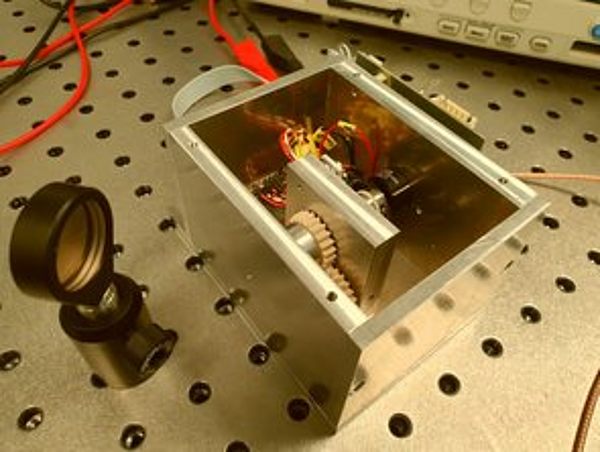

Polarization-maintaining properties of the polymers and the photolithographically fabricated structures are evaluated using a by the Institute of Electrical Information Technology specifically constructed measuring tool. The polarization state of the electromagnetic radiation is here determined by utilizing a combination of waveplate and polarizer, measuring of intensity and automatically, computer-assisted data acquisition.

Construction and realization of this system were carried out in the context of a student final thesis.

Richter, Andreas (2018): Konstruktion und Aufbau eines Polarisationsmesssystems für Laserstrahlung bei einer Wellenlänge von 1550 nm. Master's Thesis. Clausthal University of Technology, Clausthal-Zellerfeld. Institute for Electrical Information Technology.

We routinely offer more exciting topics for theses: current offers (PDF, in German).

This project in the media (German)

- Clausthaler Materialforscher setzen auf Biologisierung, TU Nachrichten, 06.03.2019

- Hektik und Husten sind verboten, Goslarsche Zeitung, 04.12.2018

- CZM: Neuer Reinraum ermöglicht Hightech-Forschung, TU Nachrichten, 03.12.2018

Scientific Assistant

Tel.: +49 5323 72-4964

E-Mail: ziemer@iei.tu-clausthal.de

Forschungscluster

Polymersysteme, Mikrosensorik und Biologisierung (Informationsbroschüre)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/b/2/csm_KT_MPV_1a049c53c4.jpg)