In-Operando vibration analysis of technical systems with Laser Doppler Vibrometry

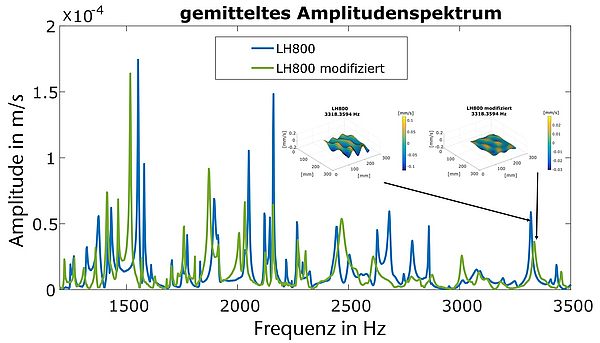

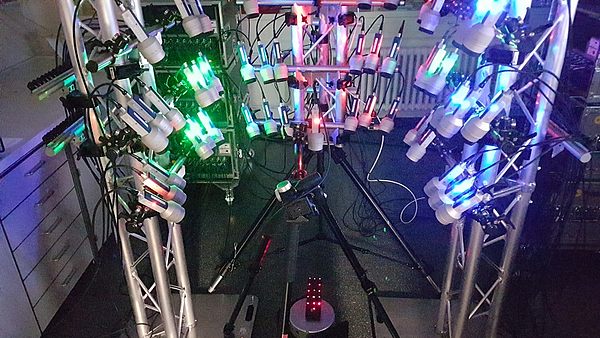

Structural Health Monitoring (SHM) with Multipoint Vibrometer

State of the art / motivation

- Single-point data acquisition for transient oscillations

- Full-Field data acquisition by 3D Scanning Laser Doppler Vibrometry for steady-state oscillations

Methods

- Additional local resolution via parallel techniques with Multi-Channel Vibrometer for transient oscillations

- Usable oscillation shapes up to 100 kHz from the use of laser excitation

Publications

- X. Cao, C. Rembe:

Non-Contact Damage Detection under Operational Conditions with Multipoint Laservibrometry.

In: sensors (Special Issue: Full-Field Optical Measurement Techniques for Damage Assessment). Vol. 20, Issue 3, 732, Jan. 2020.

DOI: 10.3390/s20030732 - X. Cao, B. Tarigan, C. Rembe and H. Schwarze:

Vibration-based white etching cracks detection at rolling contact bearings.

In: tm - Technisches Messen. Vol. 85, Issue 6, pp. 443-453, June 2018.

DOI: 10.1515/teme-2017-0141 - X. Cao, B. Tarigan, H. Schwarze and C. Rembe:

Damage Identification at rolling contact bearings.

In: tm - Technisches Messen. Vol. 84, Issue s1, pp. 34-41, Sept. 2017.

DOI: 10.1515/teme-2017-0029

Planar vibration measurement with Laser Doppler Vibrometry

State of the art / motivation

- Industrial Scanning Laser Doppler Vibrometer

- Robot-controlled 3D Scanning Laser Doppler Vibrometer

Methods

- Alternative solution by combination of a 1D Laser Doppler Vibrometer and an industrial robot

- Deployment of Multi-Channel Vibrometry

Research results

- 3D Scanning Vibrometer, realized with a single-point head and a robot, can be used flexibly for oscillations up to 23 kHz.

- Influence of specifically placed welding seams on oscillation power and attenuation can be measured with this Vibrometer Robot System.

Publications

- X. Cao, R. Schmelter, T. Ziemer, A. Lohrengel and C. Rembe:

Analyse von Plattenschwingungen mit einem robotergesteuerten 1D Vibrometer zur Charakterisierung des Einflusses lokaler Materialinhomogenitäten.

In: Fakultät für Mathematik/Informatik und Maschinenbau, Technische Universität Clausthal (Hrsg.): Technical Report Series. Fac3-16-02. Oct. 2016.

Investigation and optimization of structure-borne sound transmission in technical systems

State of the art / motivation

- Method of characterizing structure-borne sound for SDOF- and MDOF-coupled systems

- Lack of a method for areal-coupled systems

Research activity

- Mapping of the system with finite element model and adjustment of the model parameters with model updating procedures using the measurement data from the full field vibration measurement

- Calculation of the structure-borne sound transmission in the system using the adjusted model

- Optimization of the structure-borne sound properties of the system using the FE model

Research results

- Structure-borne sound energy flow on structures joined by bolted connections must be simulated with high resolution using FEM models.

- FEM models must be adapted to the physical reality via model updating procedures in order to determine the energy flow correctly.

Publications

- X. Cao, S. Backhaus, R. Scheidl and C. Rembe:

Numerical and Experimental Analysis of structure-borne Sound Transmission in Coupled Systems.

In: Proceedings of the 12th Int. Conference on Vibration Measurements by Laser and Noncontact Techniques, Ancona, Italy, 2016.

DOI: 10.1063/1.4952681 .

Tel.: +49 5323 72-2126

E-Mail: cao@iei.tu-clausthal.de

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/b/2/csm_KT_MPV_1a049c53c4.jpg)