Dynamically stable locomotion of multi-legged robots with parallel kinematic structures

State of the art/motivation

Parallel manipulators generally have increased stiffness, dynamics and guidance precision compared to serial manipulators, but in return have a smaller working space. Based on the known kinematics of the spherical parallel manipulator, the aim is to develop a mechanism that is as compact and light as possible, but still capable of bearing loads despite the reduced size of its supporting connection structures. The resulting compact, mechanically robust and highly dynamic spherical manipulator is then to be investigated and further developed for its applicability and suitability as a hip joint in walking robots, as there are only few existing investigations in this context. Furthermore, the development of a lightweight multi-legged and agile prototype robot using the modified spherical manipulator is pursued.

Methods/Procedures

The development of the individual mechanism to the complete prototype of a walking robot is carried out iteratively in individual steps. First, the single mechanism is conceptually designed and subjected to a kinematic analysis. Based on the desired kinematics, a CAD model is designed, which is largely designed as a lightweight plastic/aluminum composite using 3D printing techniques. A controller is designed on the basis of a simulation of the model and then applied to the real prototype model using real-time dSpace hardware. After the feasibility of a single joint has been verified, a complete model of a multi-legged walking robot will be optimized in simulations with respect to its geometric design, tested, a controller will be designed and then constructed as a real prototype.

Research results

Software Framework

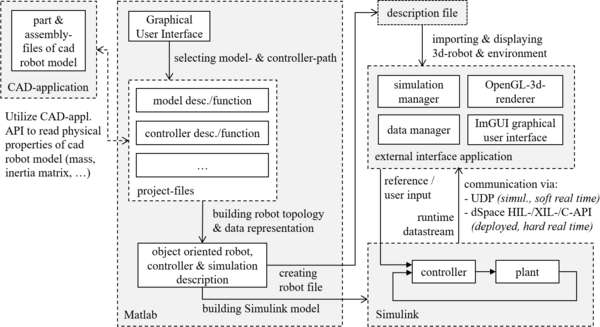

A software framework has been created which is used to automate various processes in order to accelerate and generalize the design and development of the robot prototype. The necessity to develop such a general framework results from the limitations of existing software solutions, which are suitable for the intended project only to a limited extent. The software framework forms the basis for all simulations performed, allows iterative development and fast testing of adaptations and offers a direct connection to a real prototype robot. It acts as an interface between simulation, control, CAD application, user interaction and deployment of code on real real-time hardware.

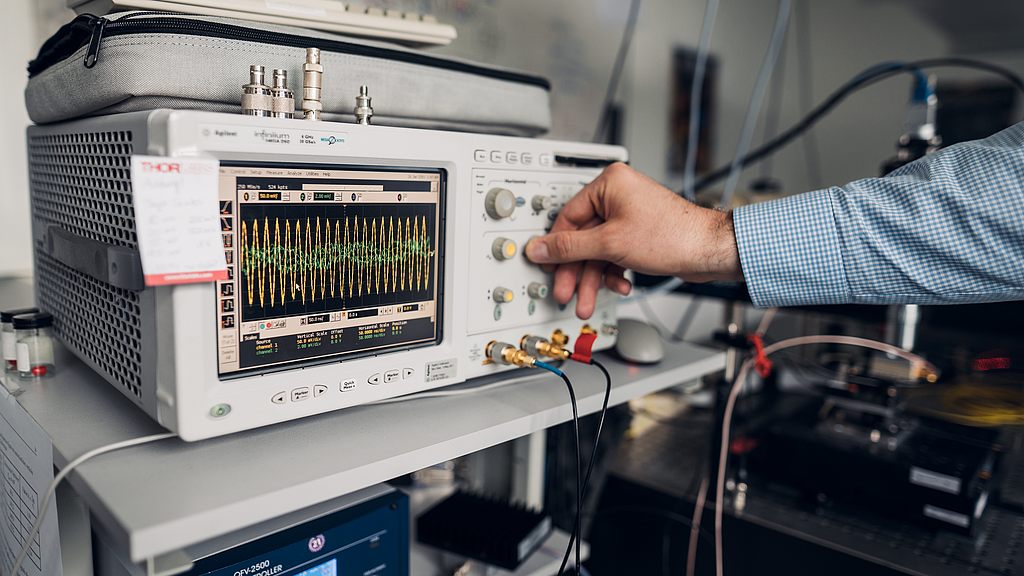

Simulations & Prototypes

A prototype model of a spherical parallel manipulator was designed as a CAD model and manufactured as an aluminium/plastic construction. By using a stereolithographic 3D printing process, highly precise and complex shapes can be designed, which allows for a spatially compact manipulator. For test purposes Dynamixel actuators are used for the application of torque. These actuators will be replaced by specialized and more powerful actuators at a later date. For test purposes the control is carried out by means of a cascaded PID control system based on the calculation of the inverse kinematics of the manipulator in simulation and in the real prototype version.